Highlights

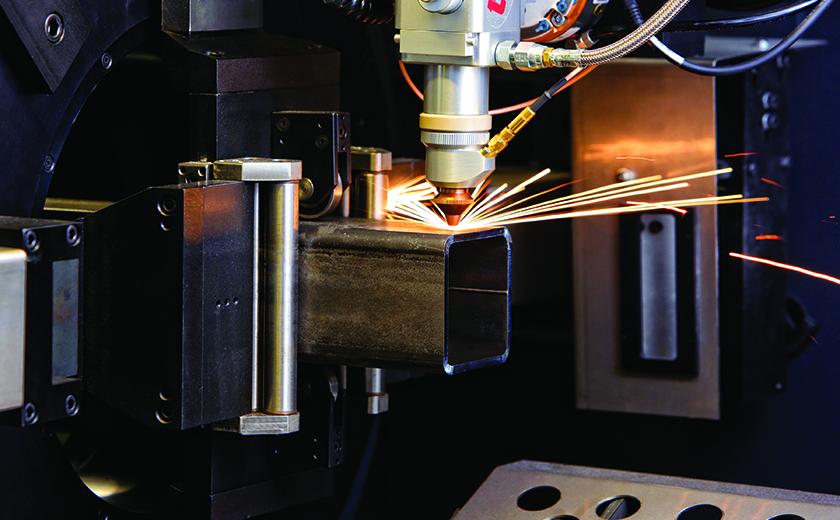

- State-of-the-art cutting head

Process tubes and profiles with high productivity. The modern cutting head features two points of crash protection – vertical and rotational. An automatic stand-off distance system maintains a fixed distance between the nozzle and the material surface for continuous, error-free cutting. - Magazine-style front loader

A 7-position magazine-style front loader makes quick work of loading tubes, clamping them in position to ensure alignment and quality cutting results. It enables loading and unloading from the same side. - Bow detection

A side-sensing laser automatically detects and compensates for any bows or bulges over the length of the tube. - Twist compensation

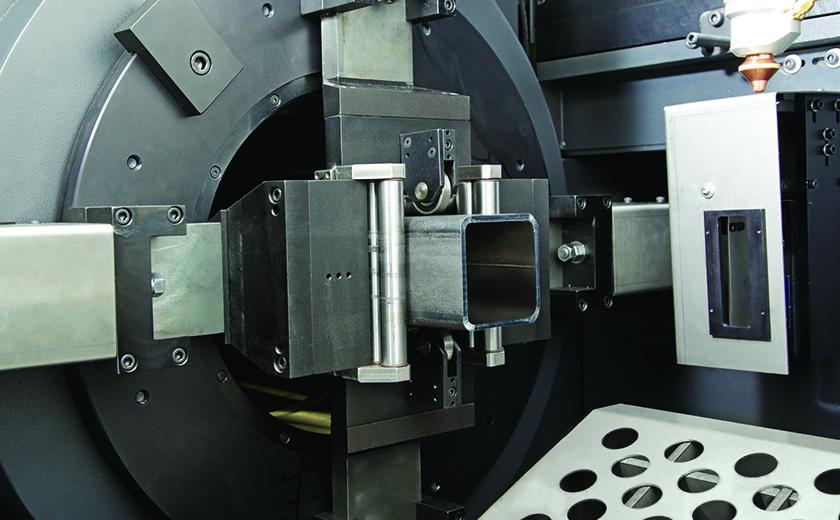

An automatic twist compensation system adapts for material deformation. - Chuck and steady rest rotary axis

A self-centering chuck automatically adjusts to different tube geometries. The servo-controlled infeed system uses multiple risers to lift the tube from the magazine to the chuck. Each riser features a tube centering device which centers the tube with the steady rest and chuck. Risers are servo-controlled and follow the contour of the tube to fully handle, turn and support the tube. - Tube cutting software

A powerful tool for the design, cutting and nesting of structural tubing, pipes and structural profiles. Add notches, tabs and features to imported parts or draw parts from scratch. Nesting single or multiple parts, kitting or combining different jobs reduces material waste and generates optimized programs.

Options

- Bundle feeder

- Customised outfeed

- Scrap and sort conveyor and drop chute

- Seam detection

- Dust collector

Models

- TL 2665-FL (3kW) or (4kW)

Tube Specifications

- Material : Steel, stainless steel, aluminium, copper, brass

- Tube type : Round, rectangle, square, ob-round

- Outside diameter / diagonal : Round: 19 x 165 mm ; Square: 127 x 127 mm ; Rectangular: maximum 152 x 50 mm

- Maximum raw material length : 8000 mm

- Maximum part length : 4800 mm

- Maximum tube weight : 32.7 kg/m

Reviews

There are no reviews yet.