HIGHLIGHTS

- 48-stations turret

A versatile mix of 48 turret stations includes four 88.9 mm indexable stations. Add multitools to further increase tooling capacity. A generous feed clearance also allows for forming. - Sleeved turret

A fully bushed turret assures superior punch and die alignment throughout the life of the Strippit VX. Individual turret sleeves can be easily replaced – no costly re-machining of the turret. - High hit rates

High/low servo controlled hydraulic ram system provides high hit rates and reduces energy consumption for efficient, productive punching operations. - Rigid bridge frame

Fully stress relieved, single-piece bridge frame and widespread axis bearing system assure machine accuracy and repeatability. - Programmable and relocatable work clamps

Three programmable and relocatable work clamps with sheet pull out sensors are automatically positioned and can be automatically relocated during a punching cycle for full sheet utilization. - Smart Stroke

Smart Stroke automatically determines the optimal tool hover height to deliver the highest punching rates possible. - Quick-change die holders

Die change system offers easy and quick die changes of 15 seconds. - Programmable parts removal chute

Programmable parts removal chute evacuates parts up to 450 x 500 mm directly under the machine table or to an optional bin-sort system - LVD Touch-P control

An easy-to-use, icon-driven touch screen control simplifies machine operation. - CADMAN® software suite

A full suite of software modules create a fully integrated process flow, including CADMAN-P punching programming software, CADMAN-SDI drawing importer, CADMAN-JOB real-time data collection, job tracking and ERP connection, as well as a Touch-i4 tablet for KPI performance indication and sorting and validating parts.

OPTIONS

- ABS automatic tool lubrication system

Air blow system automatically lubricates the punch and guide to help ensure efficient tool stripping and extend the time between regrinding. - Cooler kits

Auxiliary Hydraulic Cooler Kit and Auxiliary Electrical Cabinet Cooling Kit for operating environments where ambient temperature exceeds 35C for extended periods of time. - MOVit automation

A modular automation system further extends machine efficiency and process reliability. Choose a simple Compact Autoload, Compact Tower (CT-P) for material storage and retrieval, Flexible Automation (FA-P) for advanced loading/unloading and part picking, or full Tower Automation (TAS) or Warehouse Automation (WAS) systems. - Parts conveyor

- Rotary binsort

Models

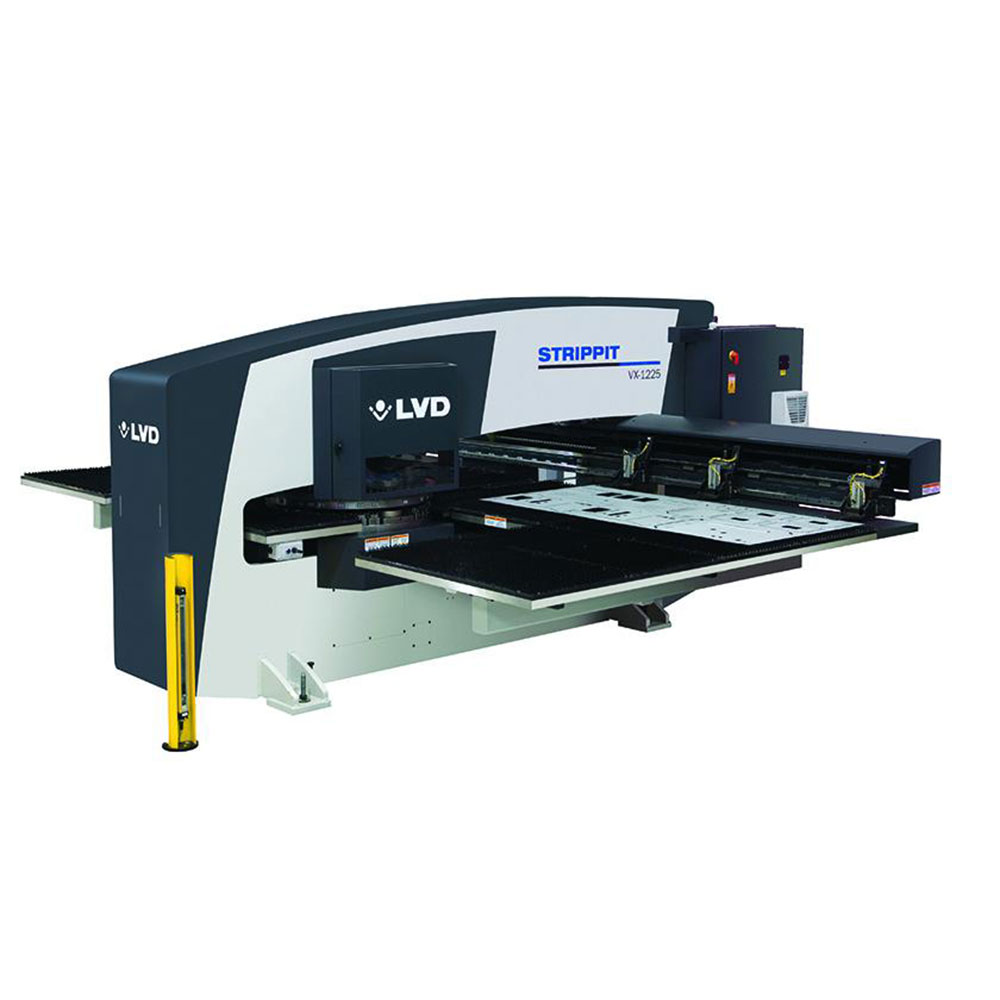

- VX-1225 (20 ton – 1250 x 2500 mm)

- VX-1530 (20 ton – 1524 x 3050 mm)

Specifications

- Maximum material thickness: 6,35 mm

- Maximum hit rate: up to 530 HPM on 25 mm centers

- Maximum hit rate: 920 HPM on 1 mm centers

Reviews

There are no reviews yet.