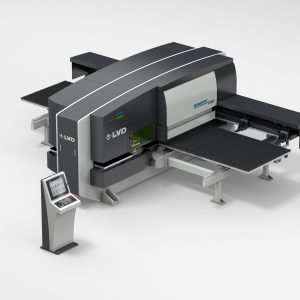

HIGHLIGHTS

- 20 indexable tool stations

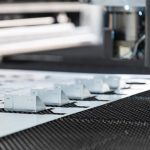

Twenty tool stations accept tools up to 90 mm and are indexable a full 360 degrees for added tooling capacity and reduced setup. Use multitools to house up to 200 tools. Strippit PX is T-style tooling compatible. - Single punch head system

The single punch head system features a retractable die to virtually eliminate any scratching on the workpiece. - Programmable and relocatable work clamps

Three fully programmable and relocatable work clamps automatically position and relocate to allow full use of the worksheet for maximum material utilization. - Energy Reduction System

An Energy Reduction System automatically reduces power consumption when the machine is idle to minimize energy requirements. - Smart Stroke

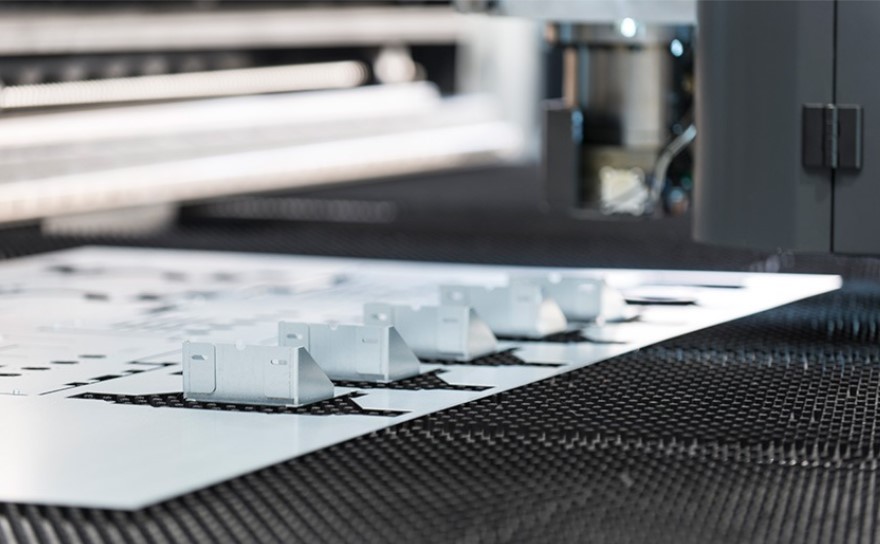

The Smart Stroke control feature automatically optimizes the ram stroke for the highest productivity – no operator intervention required. - Programmable parts removal chute

A programmable parts removal chute efficiently offloads parts up to 500 x 525 mm. Parts are separated from the sheet into a parts bin directly under the machine table or to an optional bin-sort system. - LVD Touch-P control

A touch screen control with a user-friendly graphical interface makes machine operation easy. - CADMAN® software suite

A full suite of software modules create a fully integrated process flow, including CADMAN-P punching programming software, CADMAN-SDI drawing importer, CADMAN-JOB real-time data collection, job tracking and ERP connection, as well as a Touch-i4 tablet for KPI performance indication and sorting and validating parts.

OPTIONS

- Opti-Bend tool system

Bend small boxes, brackets, knockouts, louvers and countersinks in heights up to 75 mm to eliminate secondary bending operations for a lower cost per part. - Quick Tap Tool system

A fully automatic tapping tool system allows tapping in materials up to 6.35 mm in sizes from M2.5 to M6. - MOVit automation

A modular automation system further extends machine efficiency and process reliability. Choose a simple Compact Autoload, Compact Tower (CT-P) for material storage and retrieval, Flexible Automation (FA-P) for advanced loading/unloading and part picking, or full Tower Automation (TAS) or Warehouse Automation (WAS) systems. - Extended Tool Magazine (ETM)

Holds up to 40 additional tools for ready access. Load or unload tools during machine operation. Tool changes are managed seamlessly by the Touch-P control. - Parts conveyor

- Rotary binsort

- Sheet lubrication system

Reviews

There are no reviews yet.