Highlights

• Lower total cost of ownership

PUMA focuses on getting the job done, utilising field-proven production methodologies in a lower-cost design. The machine features cost-effective components selected for their quality and reliability. Lower purchase, operating and spare parts costs will ultimately reduce the cost per part.

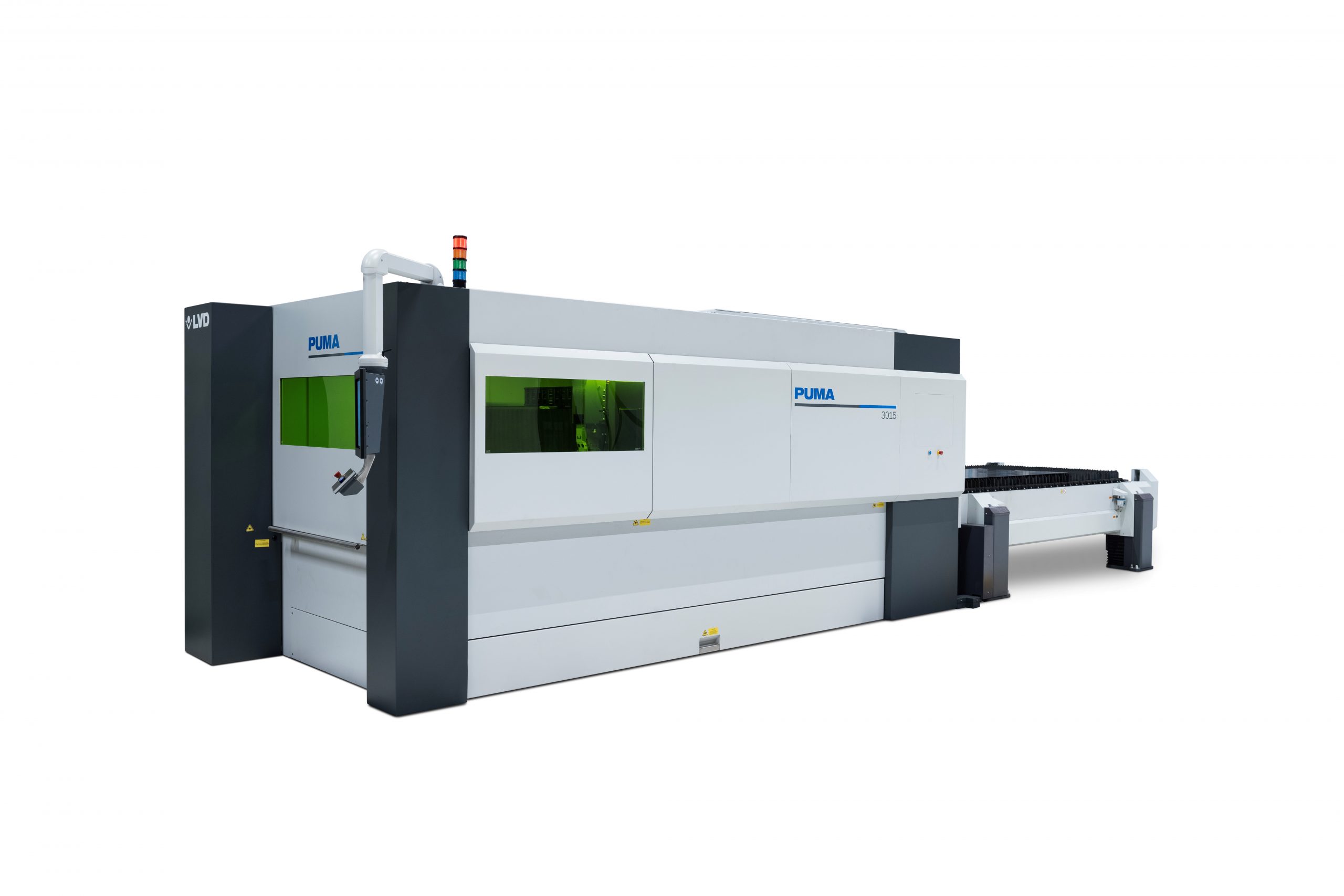

• All-round performance

PUMA provides all-round performance at an affordable price point, processing a wide range of material types and thicknesses with high repeatability. Machine accuracy is ensured by the welded steel frame construction, a feature of all LVD flatbed lasers. It provides maximum stability and minimizes deformation caused by high acceleration.

• Agility to take on any job

Designed with cost-effective operation in mind. PUMA certainly doesn’t compromise on versatility and offers peace of mind that your cutting operations will run smoothly. The machine features a range of options that increase its capacity.

• Touch screen control

LVD’s 19-inch Touch-L control simplifies machine setup and provides a graphical user interface that is easy to use and follow for the operator.

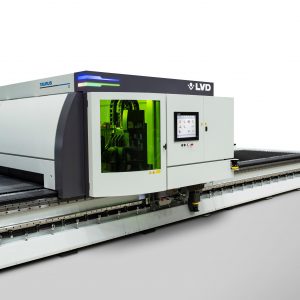

• Automatic shuttle tables

The machine maximises uptime with an integrated shuttle table system that allows one table to be loaded/unloaded while cutting on the other table. Table changeover is complete in just 35 seconds.

• CADMAN® software suite

A full suite of software modules create a fully integrated process flow including CADMAN-L laser cutting programming software, CADMAN-SDI drawing importer, CADMAN-JOB real-time data collection, job tracking and ERP connection as well as a Touch-i4 tablet for KPI performance indication and sorting and validating parts.

Options :

- Automatic nozzle changer

Fast and efficient, the automatic nozzle changer reduces non-productive time. It also performs automated nozzle inspection and cleaning to ensure reliable cutting results. - MOVit modular automation

Automate PUMA for even greater productivity. Choose a MOVit Compact Tower (CT-L) for loading, unloading and material/parts storage, MOVit Flexible Automation (FA-L) advanced load/unload systems, MOVit Tower Automation System (TAS) single or double-tower storage, or MOVit Warehouse Automation System (WAS) customizable storage tower system.

Models

- PUMA 3015, 4020 & 6020

- 3, 6 or 12 kW laser source

Reviews

There are no reviews yet.