Highlights

- Expertise

Tool design and fabrication is a critical part of LVD’s vertical integration strategy. LVD uses its high level of expertise in bending also in the development of its tooling, adopting the latest technology into the design process. - Tooling assistance

Our tooling team will evaluate your application needs and offer the best possible tooling solution for your bending operations. For custom tools, they can create a prototype to conduct bending tests using material supplied by the customer. - High-quality tooling

LVD controls firsthand the key parameters in the production process to ensure the quality and long life of the tools. - Best lead times

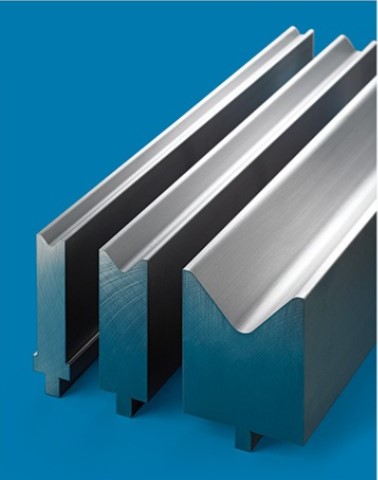

In-house manufacturing ensures better lead times than when you depend on third-party suppliers. We hold a huge number of standard tooling in stock so can usually dispatch orders very rapidly. - STONE radius

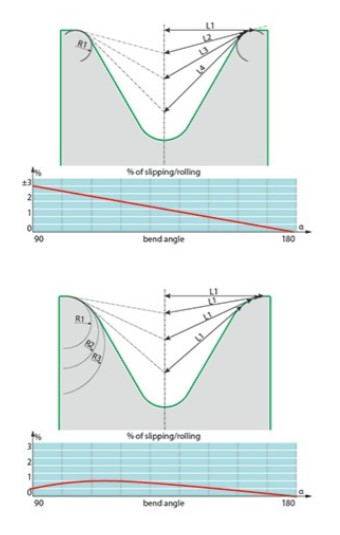

Shaped Tooling for Optimal beNding without wEar. Developed by LVD, this progressive radius on both sides of the V opening reduces friction between the material and the die to minimise part marking. - Inductive hardened

The tools are hardened up to a minimum of 56 HRC, making them stronger, durable and incredibly wear resistant.

Reviews

There are no reviews yet.