Highlights

- Handling large-scale panels

LVD’s panel bender models address diverse production needs in a wide range of applications offering high precision production of panels including cabinet components, architectural building panels, photo-voltaic components, trailer side panels, lighting, shelving, industrial equipment, elevators, steel furniture, fire doors and clean rooms. - Full automation for high productivity

The fully servo-driven system provides precise control over the bending process providing high repeatability and high productivity. It includes automatic sheet feeding, tool setting, servo bending, clamping, feeding, sheet rotation and positioning and gauging. Unloading and stacking are available as an option. - Cost-effective machine

The standard models keep the cost of the machine competitive and can be further customised for maximum performance. The servo-driven design requires low service and is almost maintenance-free. At fixed intervals all the moving parts are lubricated via a centralised lubrication system. - Multiple-stack loading

An automatic pick-and-place system allows to load from multiple stack locations onto the auto-feed. The ability to vary sizes and thicknesses provides greater flexibility. - User-friendly parametric programming interface

Programming can be done offline – by entering the bend parameters and loading the program – or directly on the machine, even during bending. Speeds are automatically calculated based on the sheet dimensions. - One set of tools for a variety of profiles

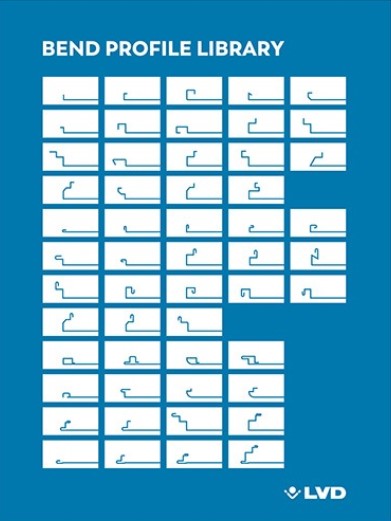

With a universal set of servo-operated up-and-down folding blades, LVD panel benders can process a wide range of profiles and various types of bends. The majority of the profiles can be bent with just one set of universal bending tools. Bends include : positive and negative bends, open and closed hemming, up and down hemming, offset bends, radius bends and closed bends.

Options

- CLA arrangement for localised bending

- Small width folding attachment

- Optional offloading and stacking system

Models

- PB 21/12

Reviews

There are no reviews yet.