Highlights

- Highly cost-competitive

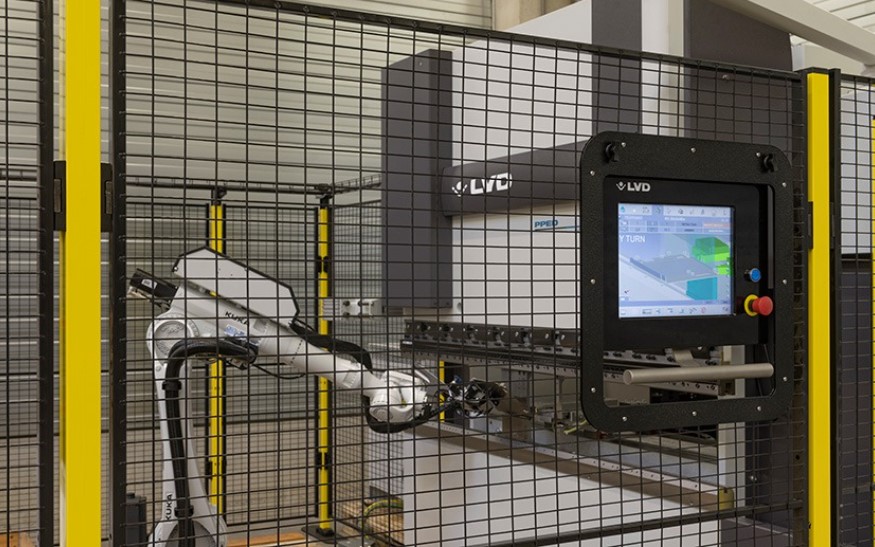

D-Cell provides automated bending functionality at an affordable price, featuring a PPED press brake and Kuka industrial robot. The cell keeps your cost per part as low as possible. - Robust hydraulic press brake

A PPED 50/20 hydraulic press brake has 50 tons of pressing force and a 2000 mm working length. Accurate and consistent bending results are ensured by the rigid, welded one-piece frame, high-quality hydraulic components and high-precision linear encoders. - Unique programming

It takes the CADMAN® software just 10 minutes to automatically generate a bending and robot program and only another 10 minutes for set-up and production of the first part. Operators of all skill levels can work with the cell. - Versatile gripper

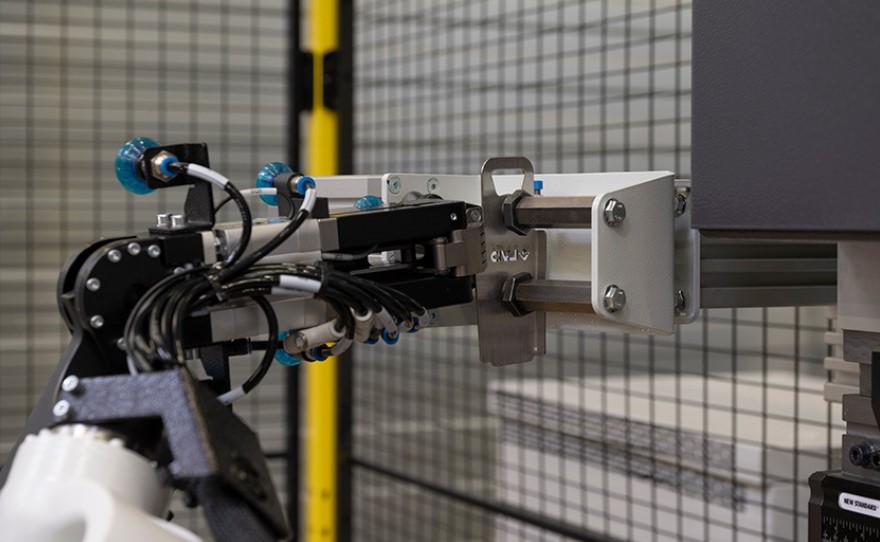

A universal gripper designed by LVD effortlessly handles different part sizes, bends three flanges without regripping and easily moves between the tool stations. - Automatic or manual operation

D-Cell offers the flexibility to also work in manual mode as the fingers of the four-axis backgauge are adapted for both robotic and manual bending. - CADMAN® software suite

A full suite of software modules create a fully integrated process flow, including CADMAN-B bend programming software, CADMAN-SIM robot software, CADMAN-SDI drawing importer, CADMAN-JOB real-time data collection, job tracking and ERP connection, as well as a Touch-i4 tablet for KPI performance indication and sorting and validating parts.

Options

- Extra input pallets

Additional input pallets for 2, 4 or 9 stacks are available.

Models

- D-Cell 50/20

Reviews

There are no reviews yet.