Highlights

- Efficient material handling

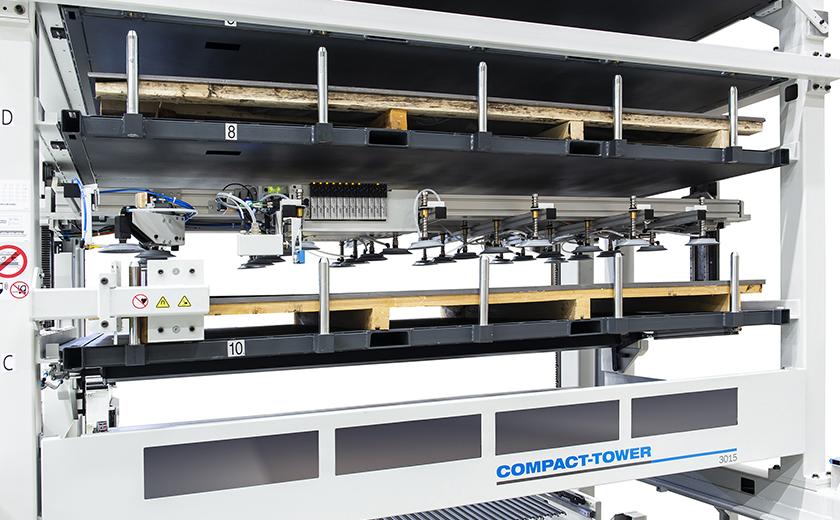

CT-L 3015 handles pallets with a capacity up to 3000 kg and a stacking height of 240 mm for loading and 180 mm for unloading including the pallet. Unloading finished parts and loading the next sheet takes only a little more than two minutes. - Forks carriage

An integrated carriage loads the raw materials and stacks finished parts on the unload pallet. - Automatic zone selection

The number of suction cups activated depends on the sheet size. Custom suction cup groups can be implemented for frequently used formats. - Thickness measurement

Sheet thickness inspection prevents processing double sheets or parts of the wrong thickness. - Touchscreen interface

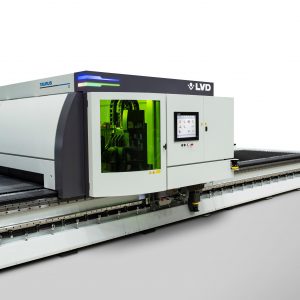

LVD’s 19″ touch screen control features intuitive graphical icons used to control all automation parameters for fast and efficient operation. - Future retrofit

This MOVit modular automation unit can be added as a retrofit in the future.

Options

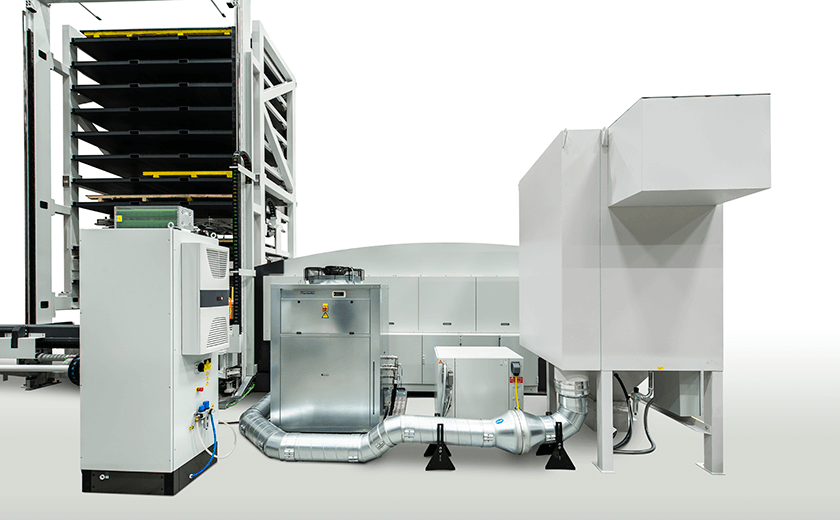

- Extra pallet

Additional pallets for easy changeover of pallets filled with finished parts. - Flexible configuration

Choose a tower comprised of 4, 6, 8 or 10 pallets with the option to configure pallets as load or unload pallets. - Teflon strips

The addition of Teflon strips provides a non-stick surface and reduces scratching while unloading.

Reviews

There are no reviews yet.