HIGHLIGHTS

- Thick turret punch press

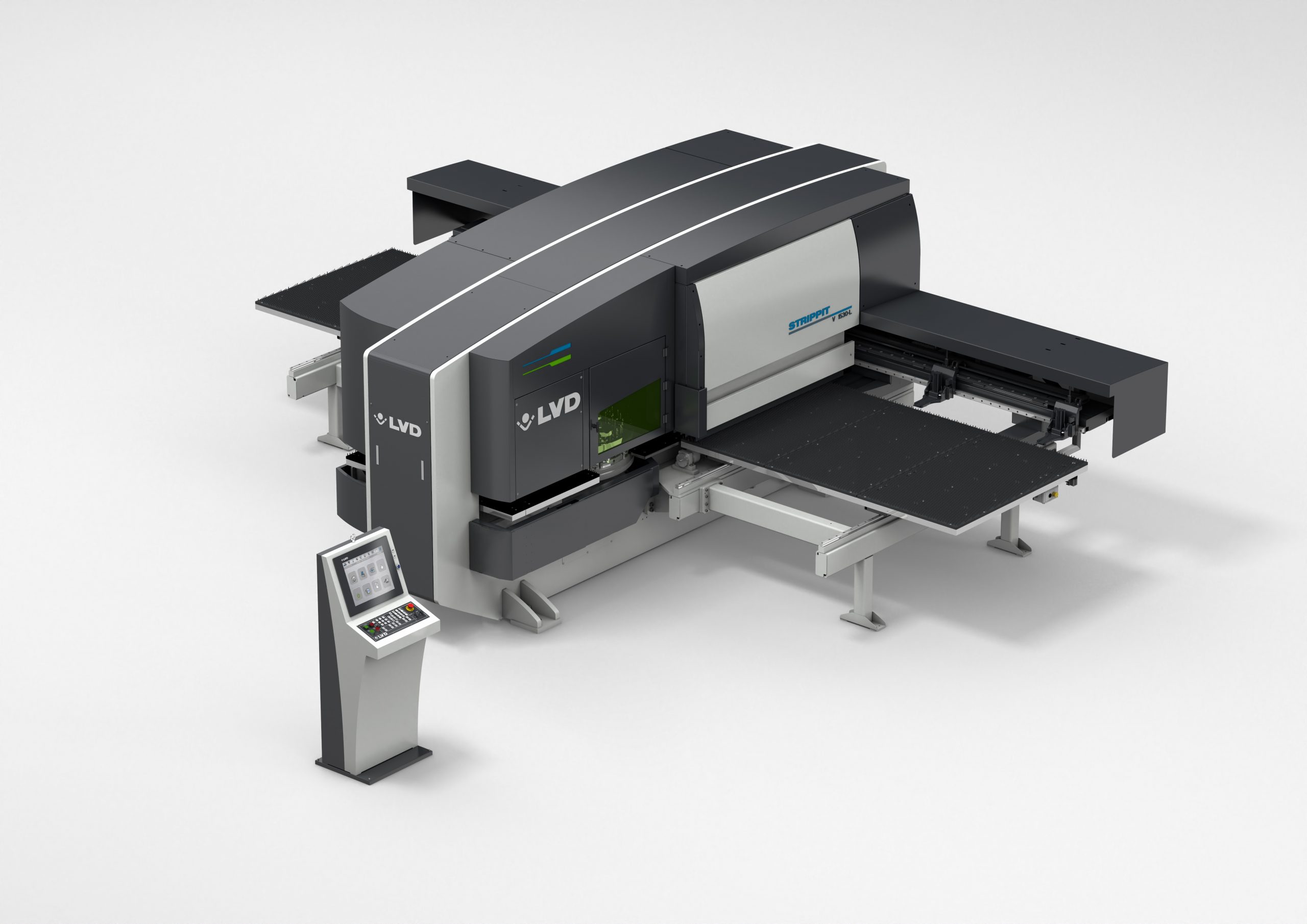

The Strippit V is a high-speed 30 ton hydraulic punch press built on a heavy-duty bridge frame for exceptional stability and punching accuracy. - High production capacity

The punch press features 48 thick-turret tooling stations with four 88.9 mm auto-index stations. This versatile mix of stations – able to accept forming, embossing, louvering, wheel and tapping tools – maximises tooling capacity and reduces set-up time for high production capacity. - Sleeved turret

Hardened turret sleeves ensure accurate punch and die alignment throughout the life of the machine. Sleeves can be easily replaced, eliminating the need for costly re-machining of the turret. - 4 kW fiber laser

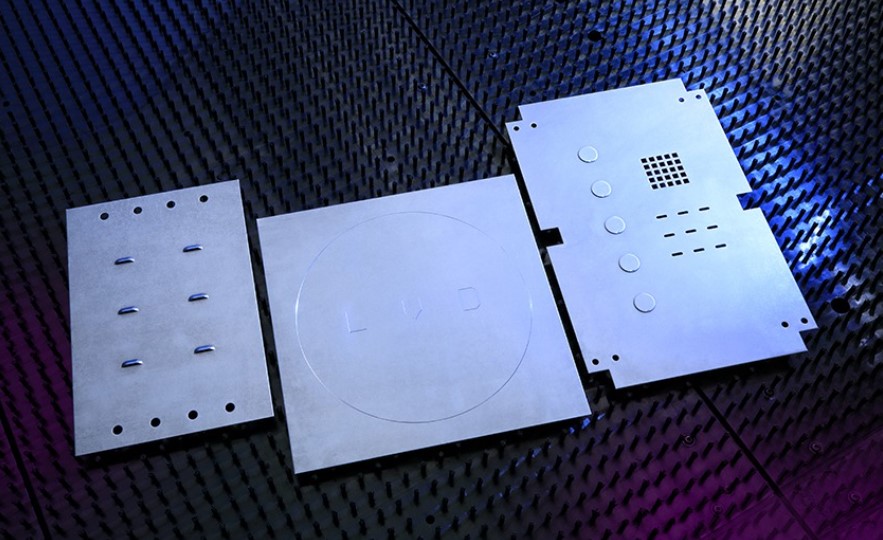

Laser cut unique shaped holes or contours and etch material with high-quality results. - Full-sheet processing

Cut and punch a full-size workpiece of 3050 x 1525 mm without repositioning to save on production time, material usage and material handling. - Large work chute for laser cut parts

A 406 mm x 1524 mm work chute for laser cut parts makes it easy and convenient to evacuate processed parts or scrap. - Smart ram control

Smart Stroke ram control automatically optimizes the punch press ram motion for top productivity. No program codes or operator intervention required. - Intuitive Touch-PL control

The latest LVD Touch interface is intuitive to use for operators of any skill level. - CADMAN-PL programming software

Integrated with the Touch-PL controller, CADMAN-PL makes programming and job set up for punching and laser cutting virtually automatic.

OPTIONS

- Modular automation systems

An automation system further extends machine efficiency and process reliability. Choose from a range of options, including Compact Autoload, Bin-sort System, Compact Tower (CT-P) for material storage and retrieval, Flexible Automation (FA-P) for advanced loading/unloading and part picking, full Tower Automation (TAS) or Warehouse Automation (WAS). A robotic interface can also be integrated. - Brush table with roller balls

- Scrap conveyors

- Sheet lubrication system

Models

- V 1530-L

Specifications

- Maximum punching capacity : 300 kN

- Maximum material thickness : 6.35 mm

Reviews

There are no reviews yet.