HIGHLIGHTS

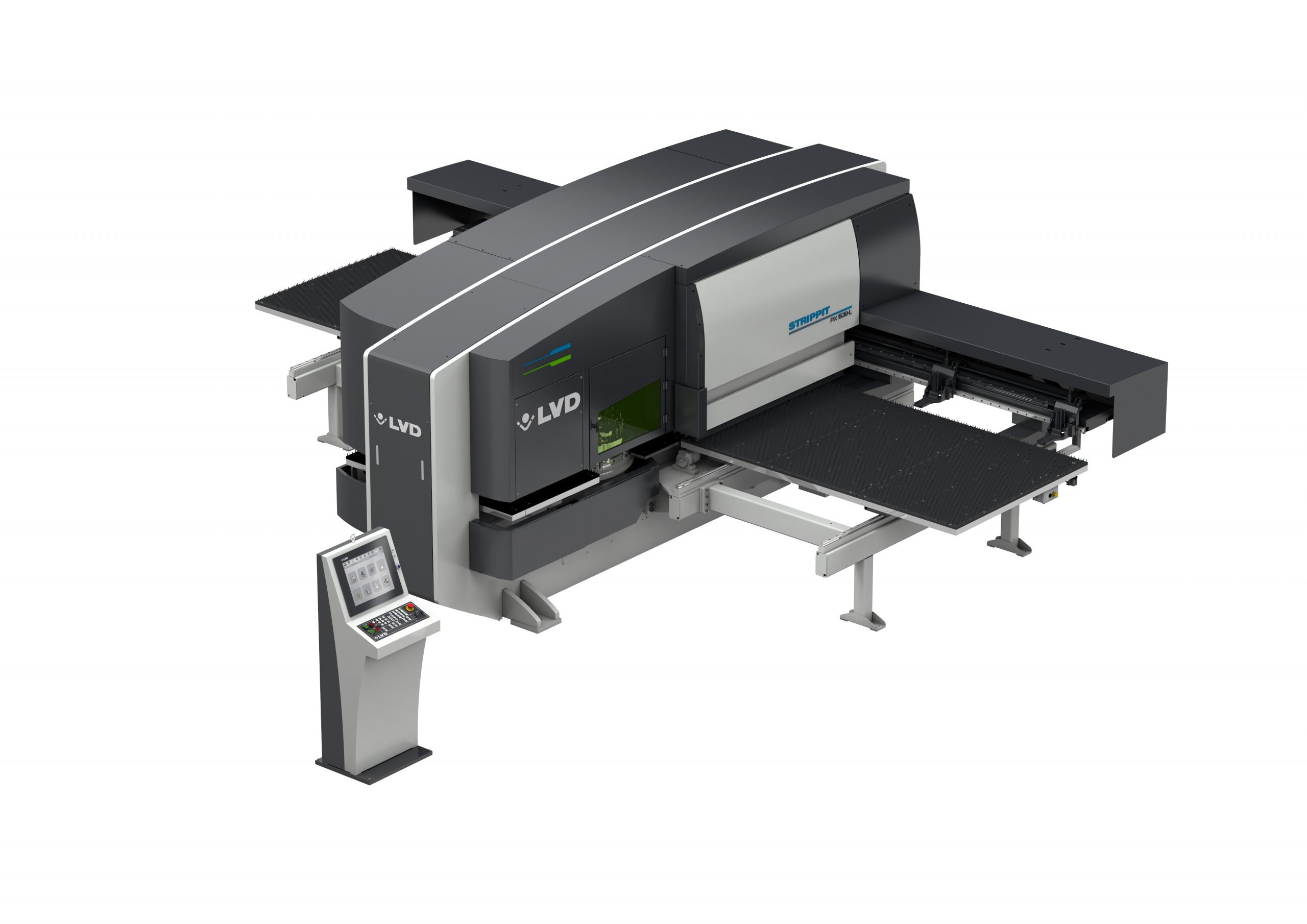

- Single-head punch press

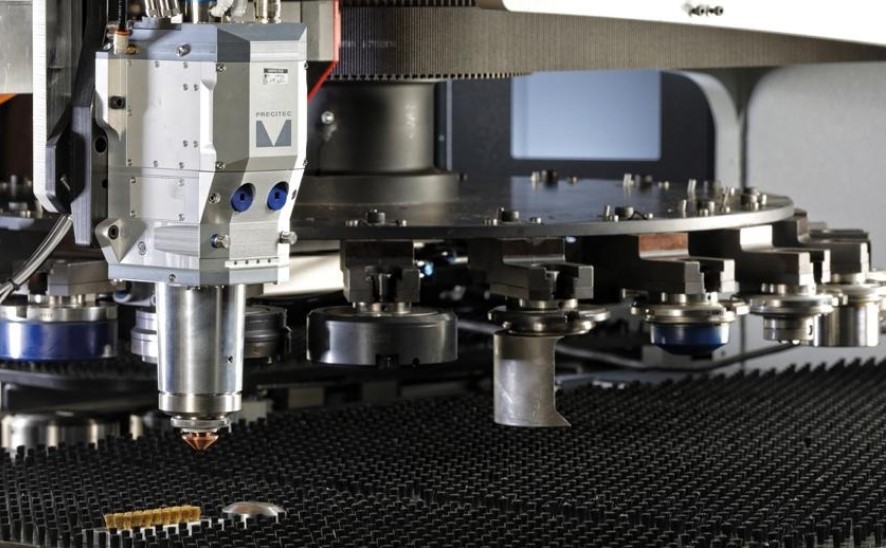

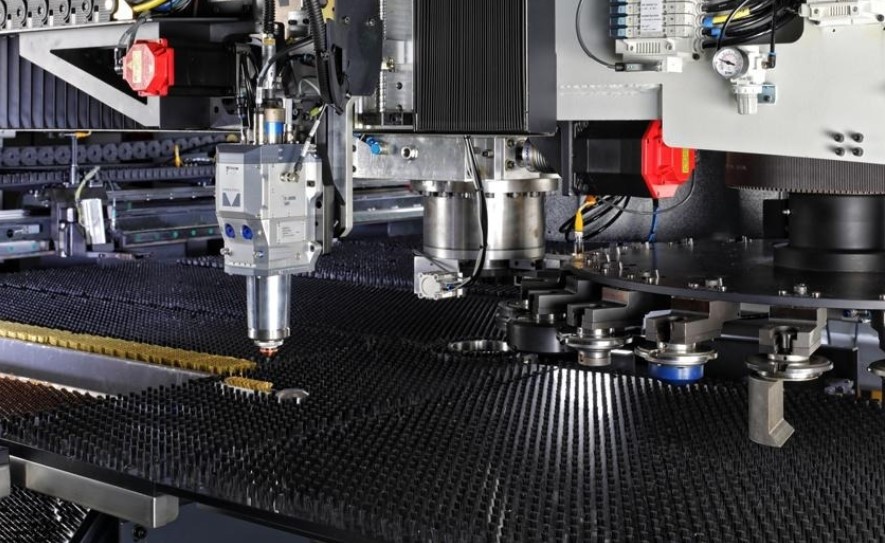

The Strippit PX single-head punch press features 20 direct-drive indexable tool stations accepting tool diameters up to 90 mm and with every tool able to rotate a full 360 degrees. - Programmable punching cycles

The Strippit PX-L has fully programmable ram cycle profiles for punching, forming and tapping to maximize machine output. - High-speed punching, forming, bending and tapping

Punch, form, bend and tap for complete part processing including three-dimensional parts and complex geometries using the Strippit PX-L. Forming heights up to 75 mm. Punch thicknesses up to 6.35 mm. - 4 kW fiber laser

Laser cut unique shaped holes or contours and etch material with high-quality results. - Full-sheet processing

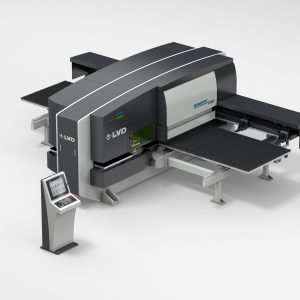

Cut and punch a full-size workpiece of 3050 x 1525 mm without repositioning to save on production time, material usage and material handling. - Large work chute for laser cut parts

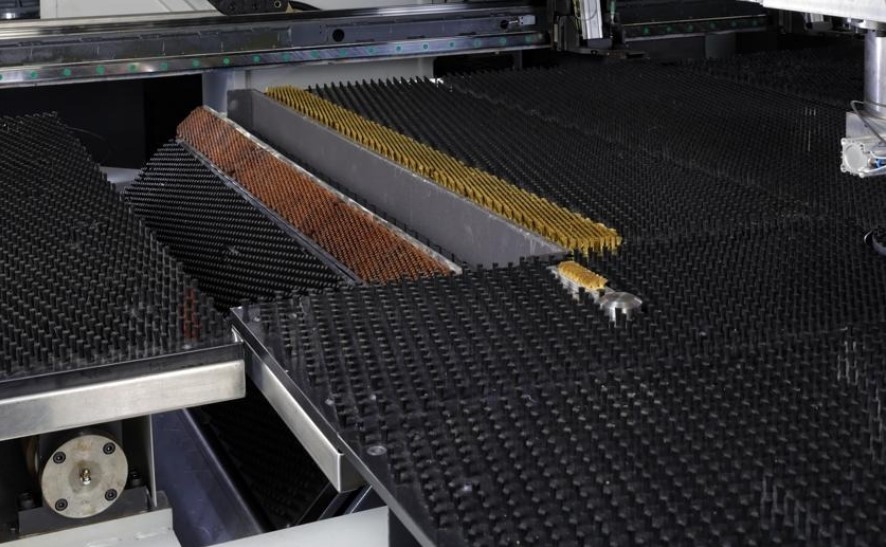

A 406 mm x 1524 mm work chute for laser cut parts makes it easy and convenient to evacuate processed parts or scrap. - Retractable die

The retractable die ensures scratch-free punching and forming. - Intuitive Touch-PL control

The latest LVD Touch interface is intuitive to use for operators of any skill level. - CADMAN-PL programming software

Integrated with the Touch-PL controller, CADMAN-PL makes programming and job set up for punching and laser cutting virtually automatic.

OPTIONS

- Modular automation systems

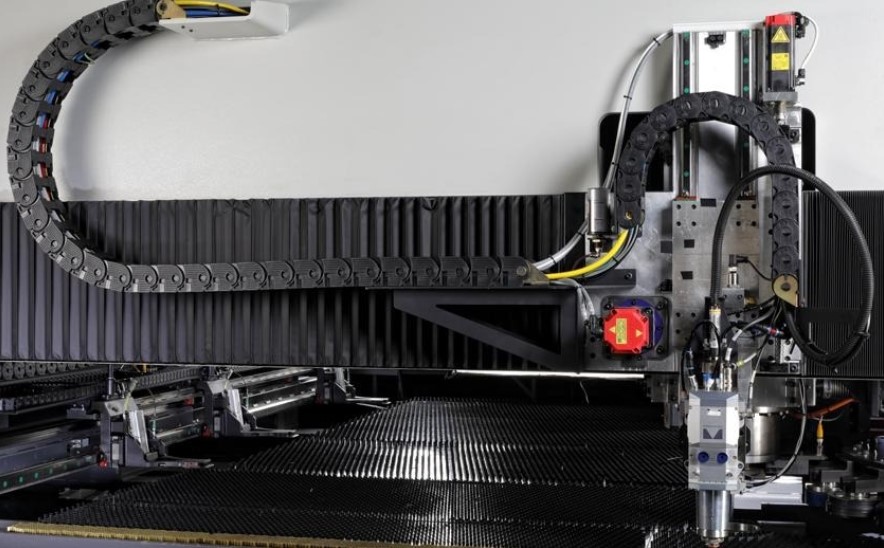

An automation system further extends machine efficiency and process reliability. Choose from a range of options, including Compact Autoload, Bin-sort System, Compact Tower (CT-P) for material storage and retrieval, Flexible Automation (FA-P) for advanced loading/unloading and part picking, full Tower Automation (TAS) or Warehouse Automation (WAS). A robotic interface can also be integrated. - Brush table with roller balls

- Scrap conveyors

- Sheet lubrication system

Models

- PX 1530-L

Reviews

There are no reviews yet.