Highlights

- Synchro-Form (EFL) adaptive bending

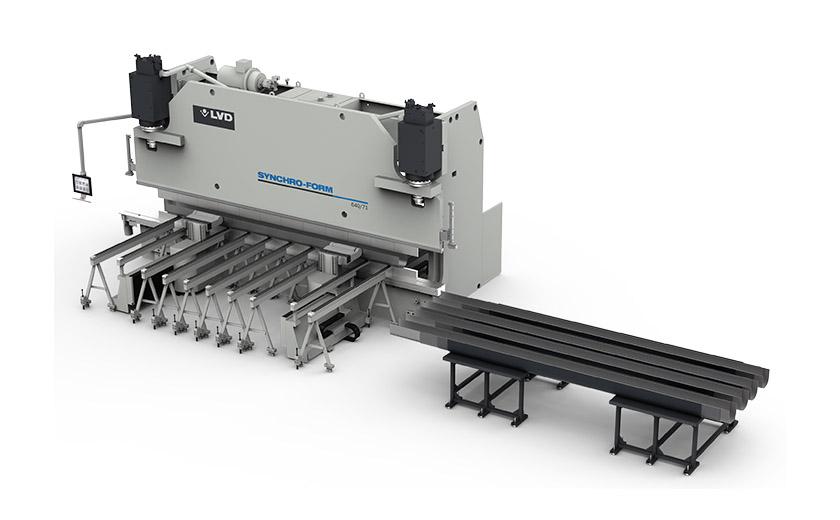

The Synchro-Form system uses synchro modules with an X-, R-, A-axis, a magnet to manipulate the parts and a laser scanner to measure the angles, position, dimension and deformation. The digital information is relayed to the LVD Touch-B control which makes adjustments to part and ram position to achieve the correct profile. - No trial-and-error bending

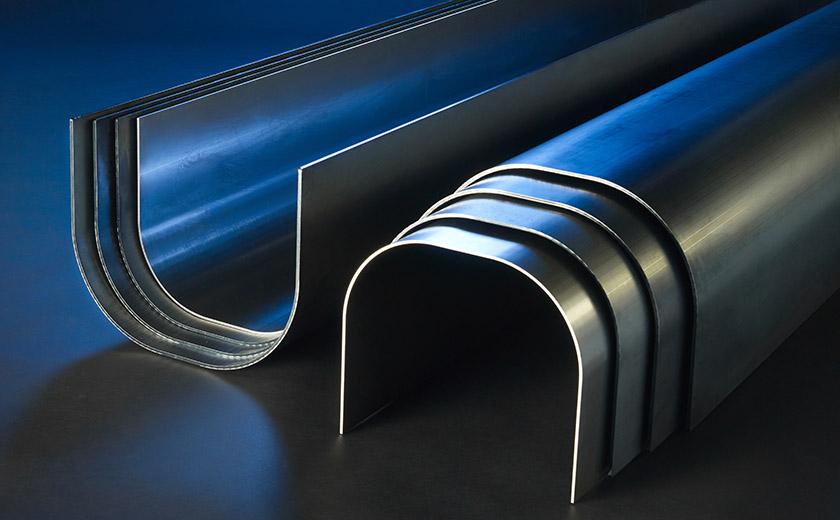

Variations are not accumulated but are compensated for in subsequent bend steps. Even after multiple consecutive bends, the profile is perfectly formed. - Heavy-duty applications

The Synchro-Form series is ideal for the production of large profiles for telescopic cranes and handlers, loader cranes, screw conveyors, bulk handling, recycling machines, cisterns, ship and plane building, steel structures, lighting poles, high masts, gas and wind power industries. - Automatic positioning

Positioning of heavy profiles is accomplished by multi-axis Synchro-modules and the front and rear magnetic positioners. Once bending is completed, the part can be extracted from the press brake. - High-strength steel materials

Synchro-Form can bend high performance materials. - CADMAN® software suite

A full suite of software modules create a fully integrated process flow, including CADMAN-B bend programming software, CADMAN-SIM robot software, CADMAN-SDI drawing importer, CADMAN-JOB real-time data collection, job tracking and ERP connection, as well as a Touch-i4 tablet for KPI performance indication and sorting and validating parts.

Options

- Configurable options at point of order: open height, stroke, throat and gap, and more

- Tooling system : Vertical load ‘W’ style top tooling, ‘W’ heavy-duty or LVD clamping are available.

Reviews

There are no reviews yet.