Highlights

- Programmable X, R or X, R, Z1, Z2 backgauge

The PPED product line includes 3 models (PPED-4, PPED-5 and PPED-7) featuring either a 2- or 4-axis backgauge as standard for greater flexibility and reduced set-up time. - CNC crowning

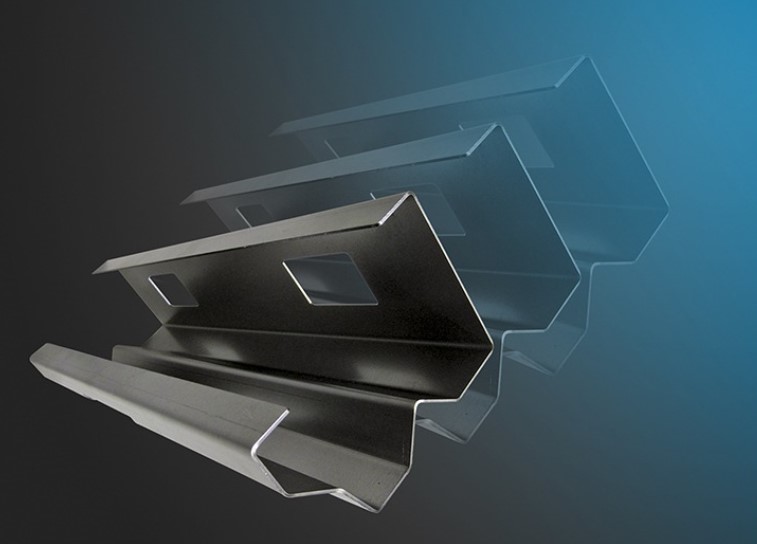

The crowning system overcomes machine deflection to assure an accurate, repeatable bend. Standard on PPED-5 and PPED-7 models. - Rigid frame design

All PPED models are designed and built utilising a welded one-piece frame machined without repositioning and stress relieved to guarantee machine precision. - Servo-controlled hydraulics

The hydraulic components are machined in-house to a high standard from a solid steel billet. - Touch-B control

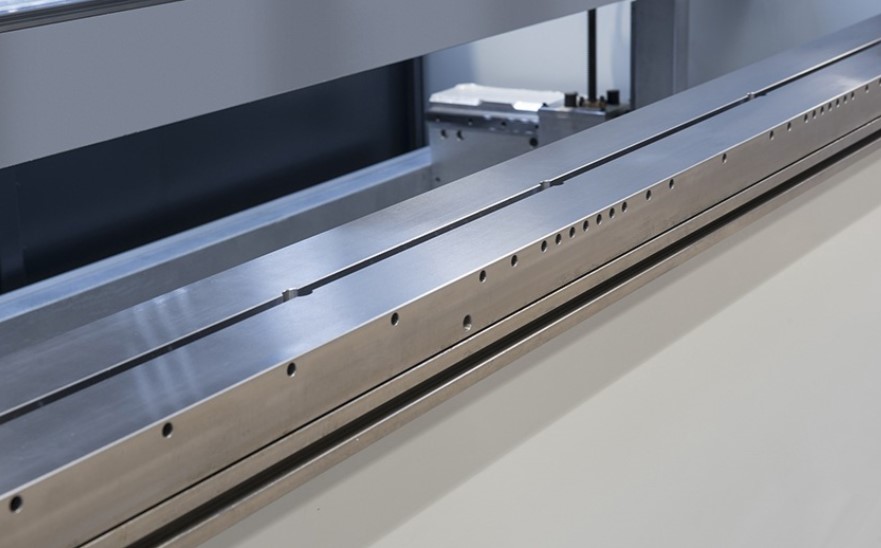

LVD’s touch screen control is simple to operate with a graphical, icon-driven user interface. It provides synchronised control of the machine allowing positioning of all available axes. - Linear encoders

High-precision linear encoders provide high positioning accuracy and repeatability. - CADMAN® software suite

A full suite of software modules create a fully integrated process flow, including CADMAN-B bend programming software, CADMAN-SIM robot software, CADMAN-SDI drawing importer, CADMAN-JOB real-time data collection, job tracking and ERP connection, as well as a Touch-i4 tablet for KPI performance indication and sorting and validating parts.

Options

- Front supports allow quick positioning along the entire bending line.

- Special colour.

- Electrical equipment 60 Hz or special voltage.

Models

- PPED-4: 2-axis backgauge (50 tons by 2 meter up to 320 tons by 4 meter)

- PPED-5: 2-axis backgauge, CNC crowning (100 tons by 3 meter up to 320 tons by 4 meter)

- PPED-7: 4-axis backgauge, CNC crowning (50 tons by 2 meter up to 320 tons by 4 meter)

Specifications

- Capacities from 50 tons to 320 tons

- Maximum bending length from 2 to 4 meters

Reviews

There are no reviews yet.