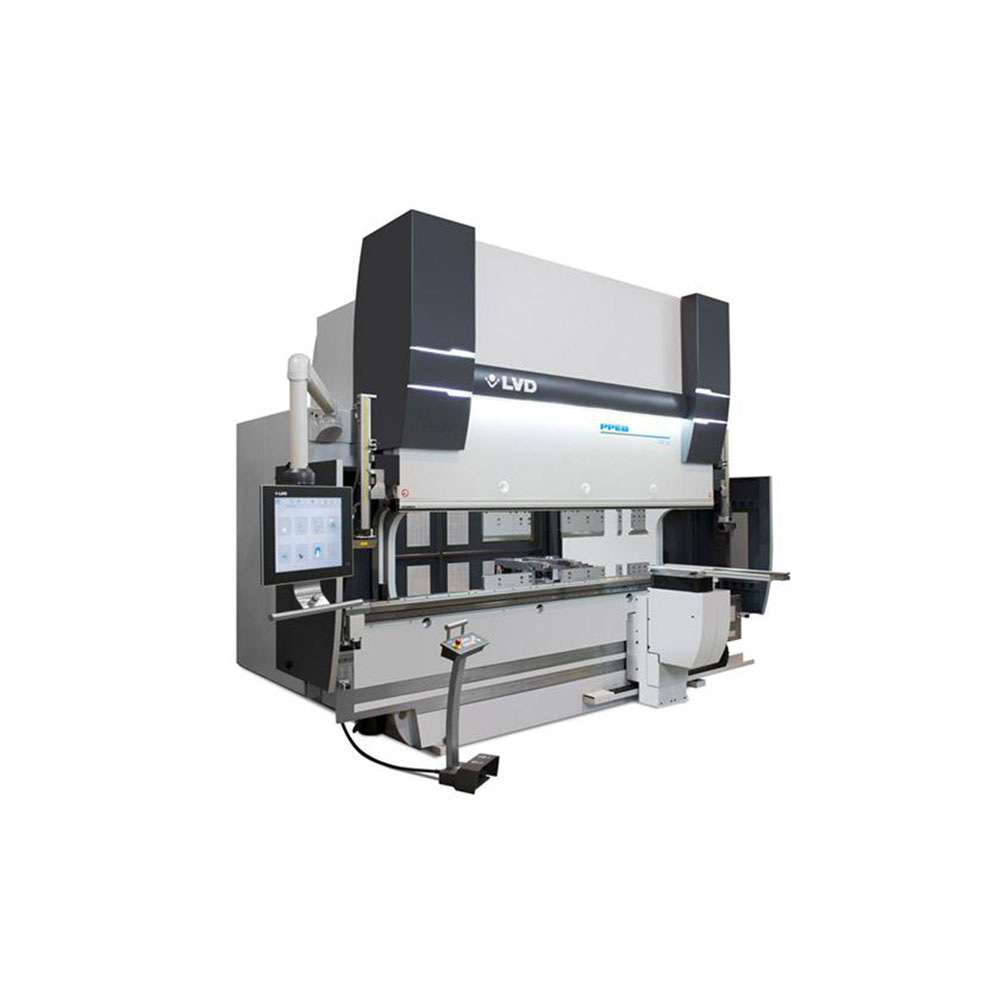

Highlights

- Tailor-made

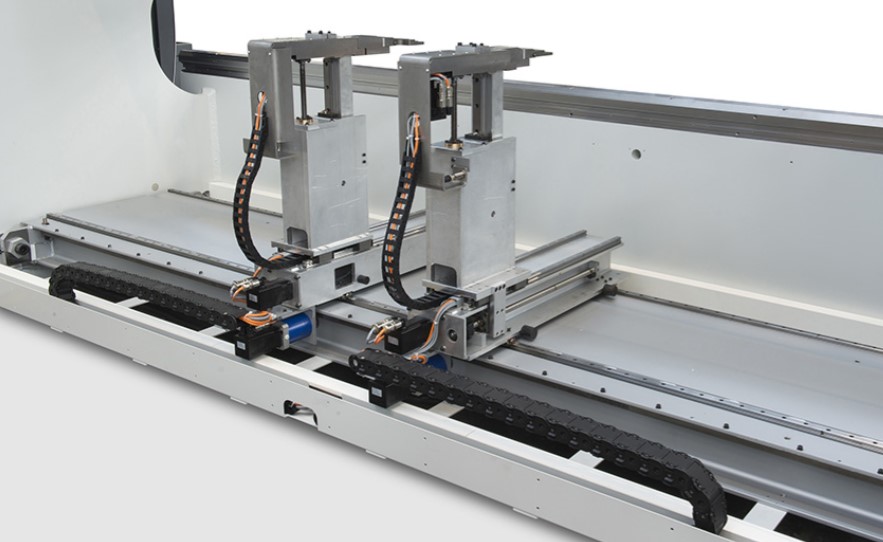

Numerous options ensure that your PPEB completely matches your application requirements: increased distance table-ram, wider table, hydraulic clamping and many more. - Flexible backgauge system

The 2-, 5- or 6-axis backgauge from X-R to X-R-Z-Z2-X; is automatically positioned for optimum bending results. - Automatic crowning

The crowning system overcomes machine deflection to assure an accurate, repeatable bend. Our wedge system is custom-made for each machine. It accounts for crowning across the full length of the bed because it’s machined specifically for it. Standard on PPEB-5 and PPEB-8. - Robust frame

A one-piece welded frame ensures machine precision. For PPEB machines up to 400 ton/4 m the frame can be installed at floor level. - Accurate hydraulic system

The servo-hydraulic system ensures that the piston at each end of the ram reaches the programmed position established in the Touch-B control. This assures a correct bend angle under the piston. - Hydraulic components

Hydraulic cylinders are machined from a solid steel billet. Pistons are steel forgings, hardened, precision-ground and mirror polished for year of trouble-free service. - Linear encoders

Linear encoders are connected to the machine in a manner that prevents deformation during bending to influence the positioning accuracy of the ram. - Touch-B control

The 19″ Touch-B control is easy to understand and simple to use. It’s easy operation helps reduce the “art to part” production time. - CADMAN® software suite

A full suite of software modules create a fully integrated process flow, including CADMAN-B bend programming software, CADMAN-SDI drawing importer, CADMAN-JOB real-time data collection, job tracking and ERP connection, as well as a Touch-i4 tablet for KPI performance indication and sorting and validating parts.

Options

- Increased stroke/table-ram distance

- Hydraulic clamping

- Front supports

- Additional gauging finger

- Sheet followers

- Hemming table

- Lazer Safe guarding system

- Robot interface

- Turbo press drive

Reviews

There are no reviews yet.