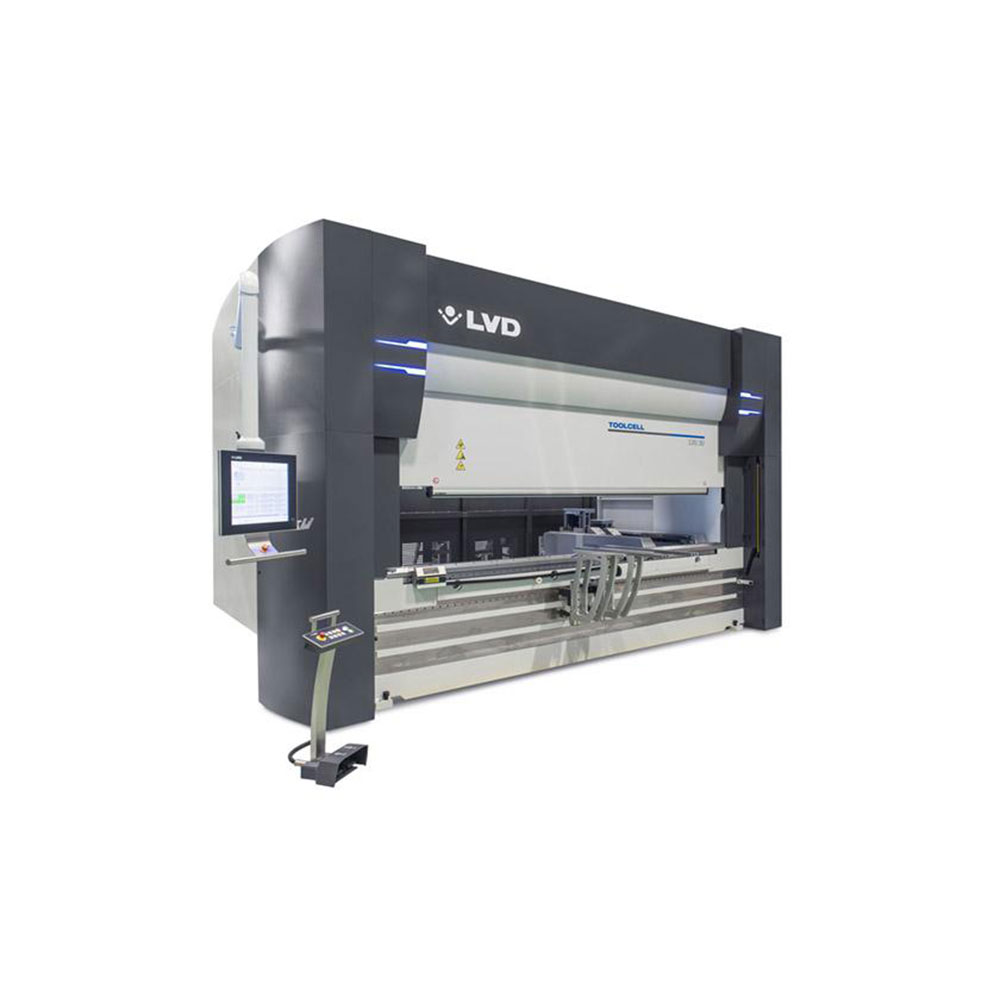

Highlights

- Automatic tool changer

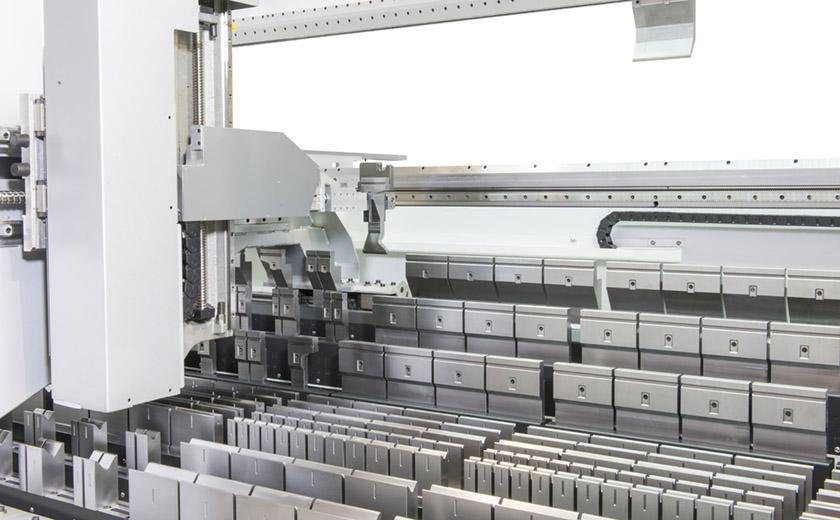

Innovative grippers built into the machine’s back gauge fingers serve as the tool changer mechanism. As the operator prepares for the next job selecting the worksheet or moving blank parts to the machine, ToolCell automatically changes the top and bottom tooling. - Intelligent tooling warehouse

The tooling warehouse is integrated into the machine, not taking extra space next to it. It is not only space-saving but also intelligently configured with all the necessary tooling for your applications. - Easy-Form® Laser adaptive bending

LVD’s Easy-Form® Laser (EFL) system ensures the first bend is accurate every time. The EFL system transmits the digital information in real time to the CNC control unit, which processes it and immediately adjusts the position of the punch to achieve the correct angle. The bending process is not interrupted and no production time is lost. - Variable frequency drive

A variable frequency drive adjusts the motor specifications to closely match the output requirements of the ToolCell resulting in considerable energy savings. - Fully equipped

Quick tool changer, large tooling warehouse, Easy-Form® Laser system, variable frequency drive, 6-axis modular back gauge and other exceptional standard features differentiate the ToolCell from other auto-tool changing press brakes. - 6-Axis modular backgauge

The backgauge can be moved in 6 axes, providing precise and automatic gauging for parallel and non-parallel parts. - Robust frame

A robust frame design ensures accuracy. All ToolCell models have a one-piece welded frame that can be installed at floor level. - Tooling range

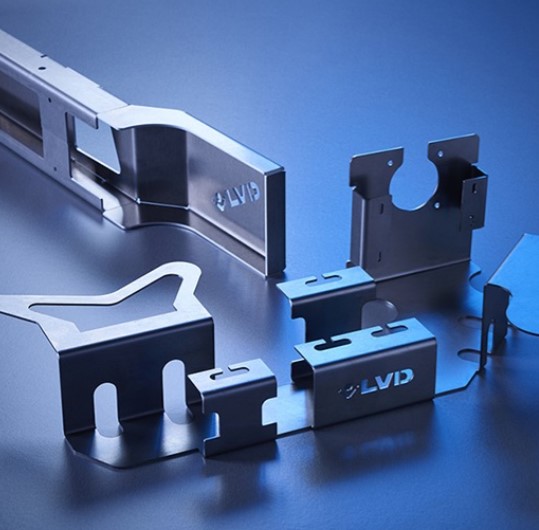

ToolCell press brakes use LVD dies and W style punches. The standard ToolCell also allows you to choose between two sets of punch and die heights: standard and taller tools to bend parts with higher flanges. - CADMAN®software suite

A full suite of software modules create a fully integrated process flow, including CADMAN-B bend programming software, CADMAN-SDI drawing importer, CADMAN-JOB real-time data collection, job tracking and ERP connection, as well as a Touch-i4 tablet for KPI performance indication and sorting and validating parts.

Options

- Front supports

Front supports on guide rails allow quick positioning along the entire bending line. - Sheet followers

Two programmable sheet followers reinforce the sheet during bending. The make full contact with the plate, preventing sheet sagging. - Increased stroke/table-ram distance

Increased table-ram distance and stroke of the ram to a maximum of 100 mm.

Models

- ToolCell 135/30, 220/30, 220/40, 220/30 Plus & 220/40 Plus

Reviews

There are no reviews yet.