HIGHLIGHTS

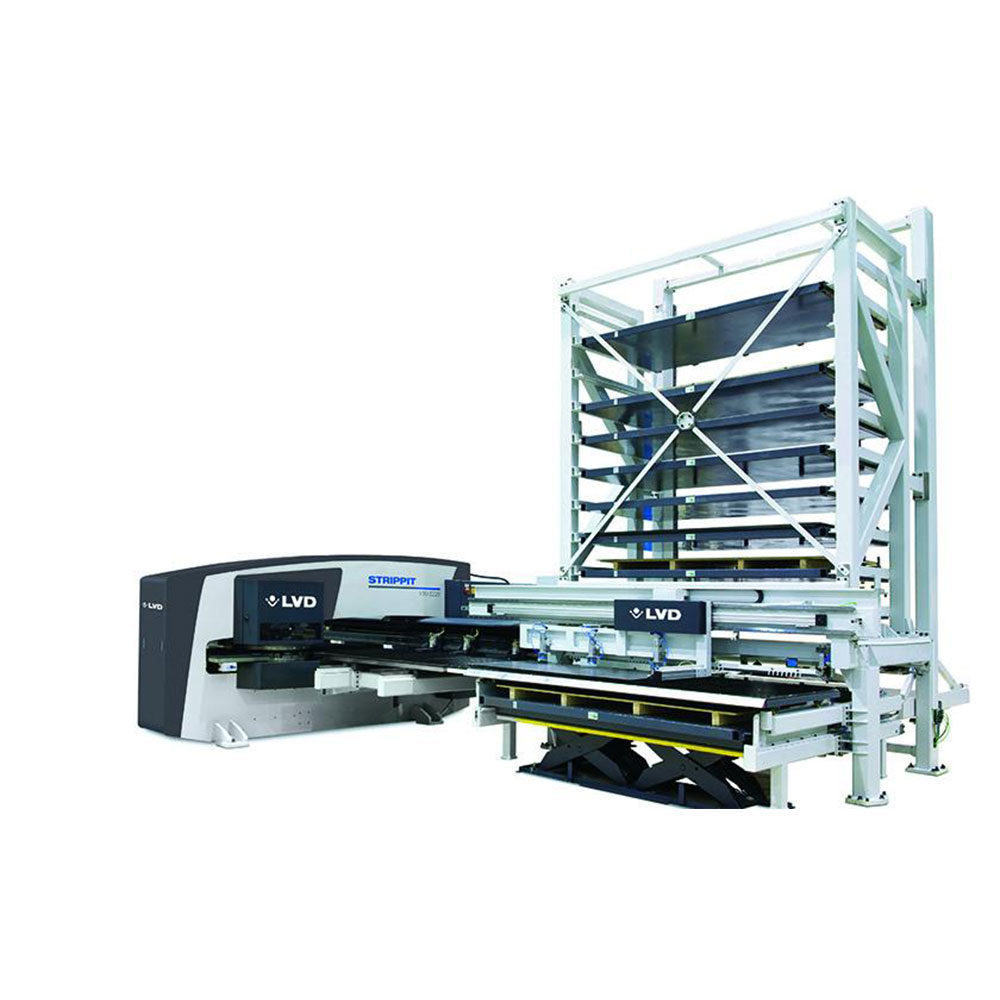

- High load and stack height capacity

CT-P handles a table load capacity of up to 3000 kg and a stack height capacity of 160 mm, excluding pallet. - Loading bridge

The unit loads material thicknesses up to 4 mm provides automatic “plate on cups” detection as well as empty stack detection for smooth, reliable operation. - Peeling system

A peeling system consists of a peeling cylinder, separation magnet, air gun and copper brush to ensure single sheet loading. - Integrated carriage

An integrated carriage allows management of pallets holding up to three tons of material. The system offers single-side unloading of finished parts and detects material stack height during each unload cycle. - Automatic zone selection

The system provides automatic zone selection depending on sheet size. All standard sheet formats are supported. - Easy-to-use controller

An integrated 19-inch touch screen controller is intuitive to use. - Factory installation or future retrofit

This MOVit modular automation unit can be installed at the factory or added as a retrofit in the future.

OPTIONS

- Additional pallet

An additional pallet configurable as a load or unload pallet is offered. This extra pallet can be used to efficiently swap out a pallet of finished parts.

SPECIFICATIONS

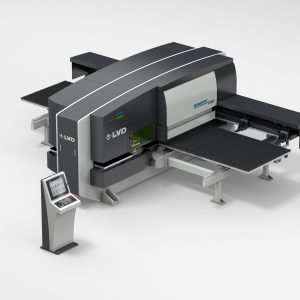

- Available models 2500 x 1250 mm and 3048 x 1524 mm

- Handles material up to 4 mm

Reviews

There are no reviews yet.