HIGHLIGHTS

- Advanced servo-electric press drive

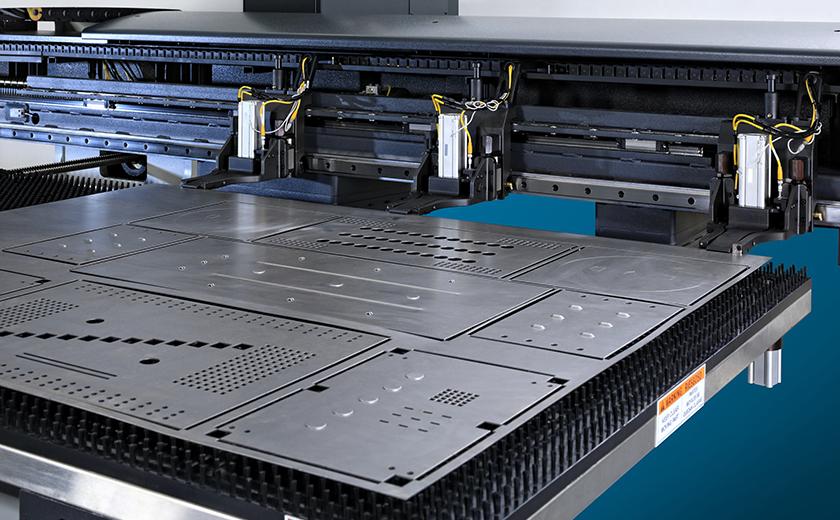

The servo-electric press drive is energy efficient – at least 20% more efficient than hydraulic designs – and economical to operate with a power requirement of just 20 kVA. It uses a minimum number of components for highly reliable operation, reduced maintenance requirements. - 47-station turret

A large 47-station turret features three 88.9 mm auto-indexable stations for tremendous tool-carrying capacity and flexibility. - Heavy-duty bridge frame

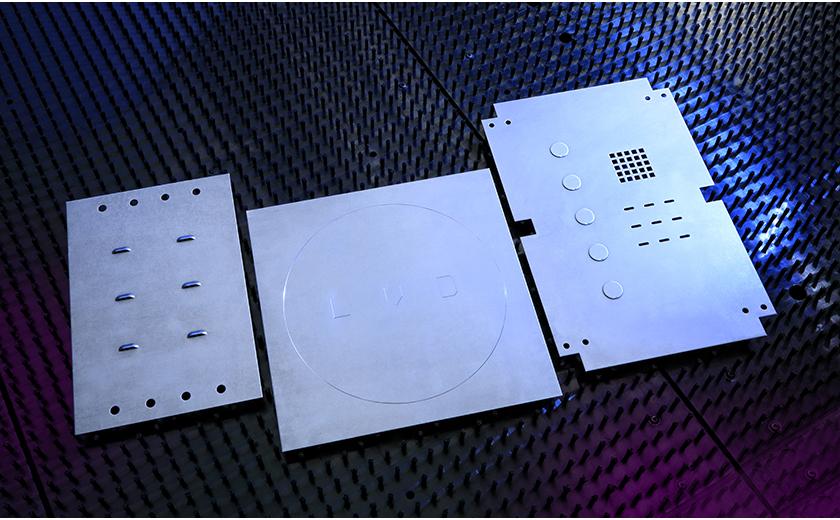

Engineered for superior accuracy and long production life, the Strippit E machine is built on a heavy-duty, closed-welded, stress-relieved frame for maximum stability. - Enhanced forming

Precise control over the ram delivers consistently accurate results for knockouts, wheel tool and forming operations, including countersinking and stamping. Ram positioning can be held to ± 0.001. A 25 mm feed clearance offers more forming capacity. - Easy setup and changeover

The Strippit E offers the easiest tool changeover in the industry. Quick-change die holders reduce setup time. - Smart clamp

Smart Clamp automatically detects exact clamp locations to provide the smallest possible no-punch zones - CNC relocatable work clamps

Automating work clamp movement reduces setup time and increases productivity. Three CNC relocatable work clamps with sheet pull out sensors are standard on the Strippit E-1530, available as an option for the Strippit E-1225. - LVD Touch-P control

An easy-to-use, icon-driven touch screen control simplifies machine operation. - CADMAN® software suite

A full suite of software modules create a fully integrated process flow, including CADMAN-P punching programming software, CADMAN-SDI drawing importer, CADMAN-JOB real-time data collection, job tracking and ERP connection, as well as a Touch-i4 tablet for KPI performance indication and sorting and validating parts.

OPTIONS

- Additional clamping

The Strippit E-1225 features two manual work clamps and is available with an optional third work clamp or optional three CNC relocatable work clamps with part pull out sensor. - ABS automatic tool lubrication system

Air blow system automatically lubricates the punch and guide to help ensure efficient tool stripping and extend the time between regrinding. - MOVit automation

A modular automation system further extends machine efficiency and process reliability. Choose a simple Compact Autoload, Compact Tower (CT-P) for material storage and retrieval, Flexible Automation (FA-P) for advanced loading/unloading and part picking, or full Tower Automation (TAS) or Warehouse Automation (WAS) systems.

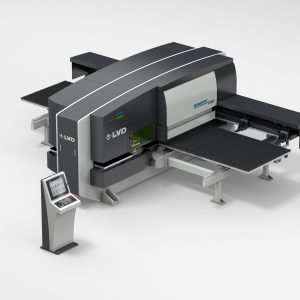

Models

- E 1225 (20 ton – 1250 x 1250 mm)

- E 1530 (20 ton – 1524 x 3048 mm)

Reviews

There are no reviews yet.